Upgrading the comforts of your home could include investing in a boiler, which might be among the most expensive purchases you make. Hence, you will do your best to avoid replacing it anytime soon. Boiler maintenance thus becomes essential to keeping your new installation working efficiently for the long haul.

But before delving into the maintenance tips for your boiler, you also might be interested in knowing the costs of installing a new one or the replacement needed and the costs involved.

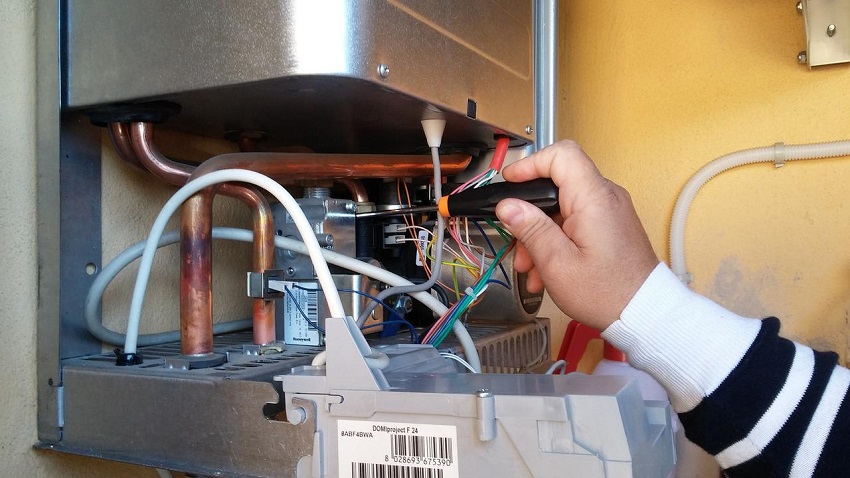

Below are a few expert tips from Corgi you can consider implementing to ensure you get it right when doing boiler maintenance:

1. Service

You are less likely to call a plumber if your boiler works without a hitch. However, servicing your unit at least once a year is vital because it can save you from costly repairs in the long run. A trained technician will inspect the boiler for leaks and other issues that could prevent it from working properly. The service will also include removing the dirt and grime gathered, which helps reduce the risk of having rusted or broken parts.

You could spend roughly £60-75 for the boiler maintenance services. Moreover, getting this service done annually can help avoid voiding your unit’s warranty lest you find yourself responsible for the repair costs down the line because you missed one service.

2. Power Flush

Sludge will build in the radiators over time, comprising dirt and rust from the water circulating when running your heating system. The sludge leads to blockages that inhibit your radiator from generating optimal heat, with the bottom feeling cold or warm instead of hot.

Experts recommend power flushing your boiler every 5 years, especially if you have hard water in your region. It would be best to consider flushing your new unit when installing it to ensure the radiators have a free flow for optimal performance. Expects the power flushing to cost you approximately £300-500, which you can recoup when you spend less on heating bills.

3. Problematic Pressure Gauge

Modern boilers come fitted with a pressure gauge display to ensure you monitor the pressure reading and act if anything is wrong. The pressure gauge has a green area on the dial indicating the correct pressure when the unit is running – usually set between one or two bars.

If the needle rests below one bar, your unit has low pressure, attributed to recently bled radiators or leaks. Therefore, assess the pipes around the boiler for leaks if you have not bled the radiators recently. Use the recommended sealer to fix the leaks. You can buy the sealer from the local DIY stores.

If you determine and fix the problem, you must repressurize your boiler system. Any pressure drops after that will require professional attention. Let an experienced engineer correct the leak or any other issues causing the pressure drop.

In some instances, the pressure might soar, in which case you can bleed the radiators to allow the pressure to escape. Ensure the valves and filling loop are properly closed if you recently repressurized your unit. If the pressure keeps shooting up, you could be dealing with other issues, and it is best to let a qualified and experienced professional inspect and fix the problem.

4. Prevailing Weather

Modern boilers have plastic condensate pipes for carrying water away from the unit to a drain situated outside the house. That means the pipes are bound to freeze during winter, which presents a challenge when you want to use your central heating system. Insulating the pipes located outside the house will help keep them from freezing.

Set the boiler to maintain the water at around 10°c flowing in the system if you plan to go away during the cold season. It ensures your unit runs periodically instead of going for long without being used. The same concern also arises during the warmer months when you use the boiler for hot water less often or not at all.

Not operating your boiler for extended periods can cause some parts to seize up or dirt and grime to build up, impacting the unit’s performance when you least expect it. Running the heating system for about 15 to 20 minutes every other week helps ensure parts are clean and moving, meaning you can enjoy a glitch-free boiler when you need it.